| • Table of Contents • |

Fall 2007 - Vol. 8/No. 1

Weed control and yield of processing tomatoes with different irrigation, tillage, and herbicide systems

California agriculture is characterized by high yields in arid areas accomplished through the intensive management of irrigated cropping systems. However, the cropping practices resulting in high yields cause potentially reduced water, air, and soil quality. The most common irrigation practice in California row crop systems is furrow irrigation. Furrow irrigation has lower water use efficiency, high rates of water outflow, more potential topsoil erosion and greater possible pesticide and fertilizer pollution than drip irrigation systems. In addition, soil beds in furrow irrigated systems are maintained by frequent tillage, which leads to high levels of dust production, possibly higher greenhouse gas emissions and reduced overall soil quality. Thus, there is a need for economically feasible alternatives for agricultural production that can reduce these environmental costs.

Conservation tillage (CT) is defined as “any tillage or planting system that maintains at least 30% of the soil surface covered by residue.” Studies have shown that CT results in the sequestration of soil carbon (C) and nitrogen (N), the reduction in air and water pollution and soil erosion, the decreased consumption of fossil fuels, and economic savings. Nevertheless, the adoption of CT as a sustainable production practice has been limited in California in part because of the need for tillage to maintain furrows for irrigation and to control weeds. Moreover, the substitution of more herbicides for weed control with reduced cultivation in CT is an environmental and economic issue for farmers. Limiting the need for herbicides by using drip systems would strengthen the potential economic benefits of CT systems. Tillage, including preplant, intercrop land preparation and in-season cultivation operations, can typically account for 18 – 25% of overall production costs in annual cropping systems in California.

Comparative studies of subsurface drip irrigation versus furrow irrigation have shown that drip is more efficient in terms of nitrogen (10-20%) and water use (20-50%) with similar or greater yield. Enhanced weed control has also been reported with subsurface drip irrigation. Thus, its use may resolve problems concerning the adoption of CT by reducing the need for maintenance of furrows and augmented herbicide use.

The objective of this study was to investigate the use of subsurface drip irrigation with CT for weed control, yield, and quality in processing tomato.

Materials, methods

A field trial at the UC Davis Russell Ranch Sustainable Agricultural Facility was established in 2003. The field was planted to wheat, which was harvested May 28, 2003, and the entire study area subsequently ripped, disked, and beds prepared for the experiment. The field trial utilized a split-split-plot design. The main plot treatments were subsurface drip irrigation and furrow irrigation, splitplot treatments were CT and standard tillage, and split-split plot treatments were herbicide and no-herbicide. The CT plots used permanent beds without bed-top tillage. The standard tillage plots used practices standard to the area (i.e. ripping, disking, landplaning and listing). The drip tape used was Queen Gil-medium flow, with four-inch emitter spacing, installed 10 inches below the surface in the center of the bed.

Tomatoes were transplanted on June 18, 2003 (cultivar ‘ENP 113’), and May 6, 2004 (cultivar ‘Halley 3155’), with a conventional three-row transplanter, modified for CT, with plants spaced 10 inches apart, as a single row on the bed. The subsurface drip irrigation plots were irrigated approximately three times per week while the furrow irrigation plots were irrigated approximately every nine days based upon evapotranspiration demand. Both systems received the same type and amount of fertilizer to avoid confounding factors associated with fertilizer.

Matrix™ was applied as a broadcast treatment to the herbicide plots. The CT plots received no tillage. The furrow irrigation-standard tillage plots were cultivated for weed control, but the subsurface drip irrigation-standard tillage plots were not cultivated in either year, because there was no significant weed growth. After harvest, all standard tillage beds were stubbledisked and mulched. The following spring, 2004, standard tillage beds were tilled using a Sundance bed disk followed by a power mulcher. Glyphosate was applied in the winter to the herbicide plots to reduce winter weed growth. A propane flamer was used to control winter weed growth prior to planting, on CT-no herbicide plots.

Weed species and density was measured along with the time taken for a crew to hoe the weeds in each plot. Weed biomass was collected from both bed and furrow prior to harvest in each plot. Tomatoes were mechanically harvested for yield determination. As each row was harvested, a subsample was taken and sorted into marketable, green, and rotten fruit. The percent of these categories was calculated to estimate marketable yield. Fruit was analyzed for pH, brix, and LED color.

Results

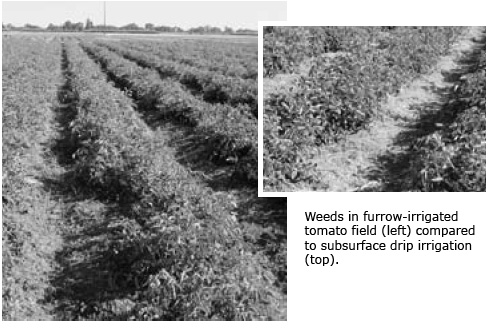

The dominant weeds in 2003 and 2004 were pigweed followed by lambsquarters and black nightshade, which made up over 85% of the weeds encountered in the study area. Weed populations increased in 2004 compared to 2003 (Table 1). Weeds were basically absent in the subsurface drip irrigation plots in either year, as the seeds could not germinate in the dry surface soil. Furrow irrigation provided ideal conditions for weed germination; the large amount of seed produced in 2003 contributed to the population increase in 2004. Herbicide or tillage reduced weed density about 50%. The tillage treatment controlled weeds on the sides of the bed and furrow, but did not control weeds in the tomato plant line. The Matrix™ treatment was effective in controlling most emerged weeds, but since overhead irrigation was not applied to this trial, the herbicide was not adequately incorporated to provide effective residual control.

Hand weeding times reflected weed density, with less hand weeding time required in subsurface drip irrigation treatments compared to furrow irrigation in both years. Hand weeding time in subsurface drip irrigation plots did not differ between standard tillage and CT or between herbicide and no herbicide plots in either year. However, on furrow irrigation-no herbicide plots, hand weeding time was nearly 16 hr/a greater compared to the herbicide plots in 2003. Additionally, CT-no herbicide plots required 10 hr more hand weeding time per acre than standard tillage plots in 2003. In 2004 furrow irrigation treatments, tillage, herbicide, or the combination of tillage and herbicide substantially reduced weed density and hand weeding time. Tillage or herbicide alone reduced hand weeding time by over 75 hr/a in furrow irrigation treatments. The combination of tillage plus herbicide treatment on furrow irrigation plots reduced hand weeding by about 20 hr/a, compared to either used alone, but hand weeding time was still greater than on the subsurface drip irrigation plots.

Weed biomass, similar to density, was highest in the furrow irrigation treatments and also highest in the furrow zone in terms of row position in both years. Competition from the tomato crop may have reduced weed growth on the beds, compared to the furrow area, where there was no competition. In 2004, there was an interaction between irrigation and herbicide on weed biomass on beds. The furrow irrigation-no herbicide plots had a much greater weed biomass on beds than when subsurface drip irrigation was used for irrigation or herbicides were used on furrow irrigation plots. Also in standard tillage plots, weed biomass in the furrows was less than the CT plots. Tillage eliminated weeds in the furrow area, but in CT plots, weeds continued to germinate and grow with each irrigation. Yields for all systems were low in 2003 due to the late planting date (Table 2). Total fruit and marketable fruit yields were highest in the furrow irrigation-standard tillage-herbicide plots in 2003. However, furrow irrigation-no herbicide plots yielded less total fruit and marketable fruit than did any of the subsurface drip irrigation treatments. The percentage of rotten fruit was greater in the furrow irrigation plots compared to the subsurface drip irrigation plots, possibly due to the increased surface moisture. In 2004, subsurface drip irrigation plots had about 10% higher fruit and marketable fruit yields than furrow irrigation plots. Herbicide treatment also improved total fruit and marketable yield by 13 to 16%, respectively, in 2004 (Table 2). All weeds were removed by hand hoeing, but herbicide treatments were able to maintain good weed control on the beds, resulting in improved tomato yields. The amount of green fruit was greater in both years in subsurface drip irrigation plots compared to furrow irrigation plots and some tendency toward less rotten, overripe fruit. This may indicate a delay in maturity in these plots, possibly indicating the need to reduce or cut irrigation earlier in the season.

There was no relation between any of the individual treatments and tomato quality in 2003, with tomato brix averaging 5.65% in the subsurface drip irrigation and 5.73% in the FI. In 2004, tomato brix was 5.01% in the FI, but only 4.72% in subsurface drip irrigation Plots. Neither pH nor LED color varied between treatments in either year.

Conclusion

This experiment demonstrated that subsurface drip irrigation could substantially reduce weed density and growth in limited rainfall environments. These data also provide insights into the weed dynamics within different irrigation and tillage systems as well as their interactions. With subsurface drip irrigation, it may be possible to implement CT systems without the typical increase in herbicide use.

This copyrighted article appeared in a longer form in Weed Technology, Vol. 20, Issue 4, pages 831-838, published by Weed Science Society of America, Allen Press Publishing Services. It is used with permission.